What is activated charcoal?

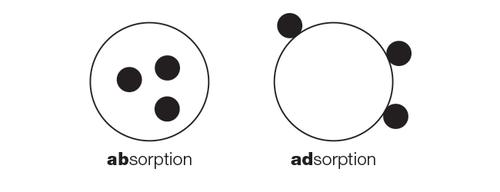

Activated Charcoal is pure carbon, and is considered the most adsorptive material in the world.

Incredibly, one gram of charcoal has the surface area of 500 to 1500sq metres, and each particle of charcoal has millions of tiny airspaces. These spaces allow activated charcoal to adsorb many times its own weight of poisons, toxins and harmful chemicals and allowing them to be flushed from the body.

There are only 3 grades of charcoal that can be taken internally – coconut shell, bamboo, and untreated hardwood, such as teak..